The Difference between High-mix Low-volume Wiring Harness Business and High-volume Wiring Harness Business

In various industries, demands of personalized high-mix low-volume products have always existed. In the past, these demands have not gained the attention of product manufacturers or service providers under the constraints of communication costs, implementation costs

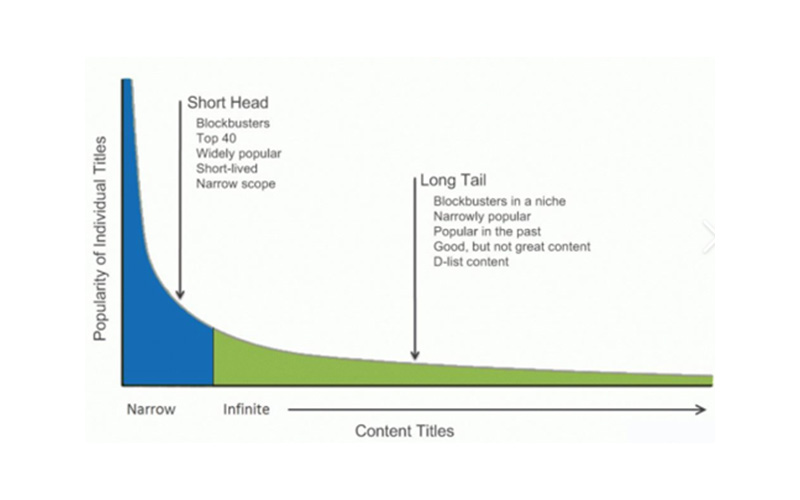

In various industries, demands of personalized high-mix low-volume products have always existed. In the past, these demands have not gained the attention of product manufacturers or service providers under the constraints of communication costs, implementation costs, and logistics costs. The popularity of communication, the rise of internet technology, and the development of global logistics have made it possible to reduce communication costs, product display costs, and logistics costs to the proper level, bringing the demands together for multiple varieties of products from all over the world to form an attractive market. Chris Anderson, the editor-in-chief of Wired magazine, fully discussed this in his book The Long Tail in 2004.

Inspired by The Long Tail, we combined our own professional expertise and work experience in 2009 to establish Shenzhen Hilink Technology Co., Ltd., positioning to meet the demand for high-mix low-volume wiring harness in the fields of industry, medical, measurement and analysis, special machinery, mining, oil, and gas, etc.

Compared with the high-volume wiring harness demands in the fields of household appliances, automobiles, communications, consumer electronics, etc., the high-mix low-volume wiring harness demands present the following characteristics:

Product Features and Standards:

- Terminal products are typically complex in structure and high in technology, and usually have requirements for wiring harnesses to be flame-retardant, low-smoke, halogen-free, phosphorus-free, EMC available, etc., and even biocompatibility requirements for medical devices. There are industry certification requirements for wiring harness suppliers, such as ISO 13485 certification for the medical industry and IATF 16949 certification for the automotive industry.

- The terminal products usually have high prices, long lifecycles, and are used in critical occasions. In serving our customers, the designed service life of Heidelberg’s commercial printing equipment is 60 years. Therefore, there are high quality standards and reliability requirements imposed on the wiring harnesses.

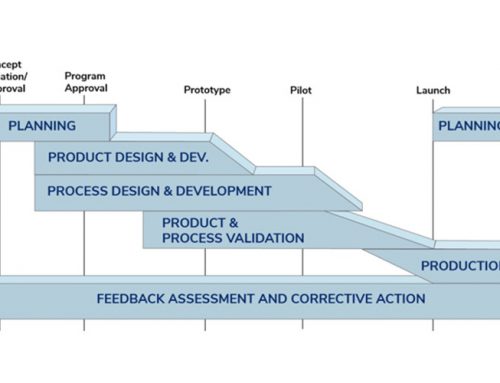

Design and New Product Introduction:

- The customer has a relatively large overall scale and is even ranked among Fortune Global 500, however, due to the low sales volume of a single product, the responsible team for a single product is relatively small, usually around 300 people, which are unable to allocate dedicated professionals for the development of wiring harness. In the process of serving customers, the wiring harness is completed part-time in many cases by electronic engineers or structural engineers who are experts in their own fields, but often lack sufficient expertise and experience in wiring harnesses. In view of this, it is necessary for the harness supplier to understand the customer’s application, follow the principles of value engineering, and combine harness expertise to provide professional harness design or optimized design support for the customer.

- Terminal products are usually customized solutions for specific application scenarios of their customers, and will be personalized or configured based on customer needs, resulting in the dilemma of standardizing the design of the wiring harness while adjusting the design based on the adjustments of the terminal products, which requires the harness supplier to work more closely with the customer and be more agile in the implementation of the wiring harness.

Supply Chain:

As mentioned above, the complex structure and high technical content of terminal products also lead to harness suppliers’ demand for connectors, wires, and other raw materials being characterized by multiple varieties and low volumes, which also leads to the following challenges:

- Wiring harness manufacturers can hardly, like their counterparts in mass production, vertically integrate the main raw materials, e.g., developing connectors and wires independently, and must rely on downstream suppliers for material supply.

- The characteristics of high-mix low-volume material demand pose great challenges to supply chain construction. It requires long-term selection and coordination to find suppliers who understand and support the high-mix low-volume demand, and it also requires a significant amount of effort from business operators and procurement personnel to establish and maintain good cooperation with suppliers.

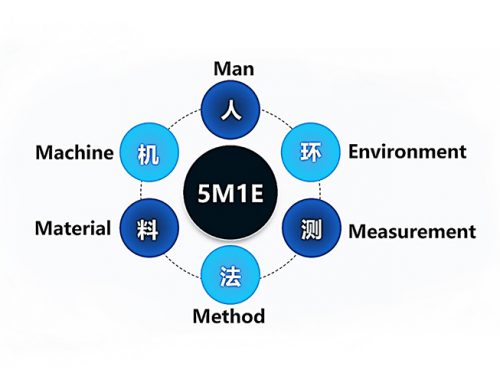

Production Organization and Quality Control:

- Terminal products are sold on a project basis, combined with frequent customization and configuration based on specific customer needs. As a result, it is difficult for customers to accurately predict their demand for wiring harnesses, requiring more robust safety stock of raw materials and greater flexibility in the production and delivery of wiring harnesses.

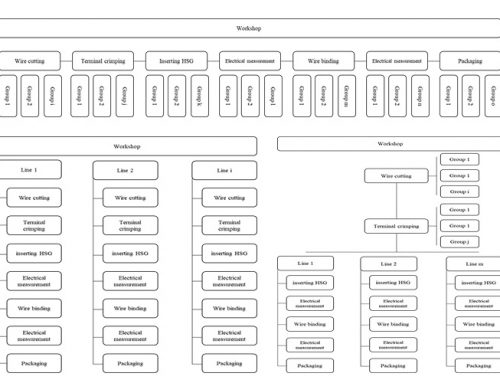

- Due to the wide variety of main materials for wiring harnesses, i.e., connectors and wires (each having 20-30 types), coupled with the fact that wires are soft and bendable, with poor straightness consistency, automation of the wiring harness production process does not make much sense without sufficient volume. Therefore, for high-mix low-volume wiring harnesses, the production mainly adopts a combination of process automation, semi-automation, and manual methods.

- Meanwhile, customers’ discrete demands for high-mix low-volume wiring harnesses (for example, 80% of our part numbers having an order quantity of less than 50 PCS), the significant differences among part numbers, and the short delivery time given by customers necessitate frequent changeovers of wires in the production process, and are not conducive to assembly line operations.

- Quality is in design, production and management. Compared to high-volume production, the high-mix low-volume wiring harnesses are characterized by the frequent changeovers of wires in production and the multiple parallel part numbers, which puts forward higher demands for quality planning and control.

In summary, although they belong to the same wiring harness industry, the business of high-mix low-volume wiring harnesses has significant differences from that of high volumes. On one hand, this requires manufacturers engaged in the business of high-mix low-volume wiring harnesses to be in response to the characteristics and challenges of their business, continuously think and solve problems, and develop their professional capabilities. On the other hand, this also requires customers to recognize the characteristics of the high-mix low-volume business of wiring harnesses, so that they can make targeted decisions in choosing suppliers by distinguishing their requirements between high-volume harness and high-mix low-volume harness.

All rights reserved: Shenzhen Hilink Technology Co., Ltd. Reprinting is welcome, but please be sure to indicate the source.