Quality Control of High-Mix Low-Volume Wiring Harnesses

Quality is the conformance of the products or services we deliver to our customers with what we promise them. A consistent process determines consistent results. To ensure quality

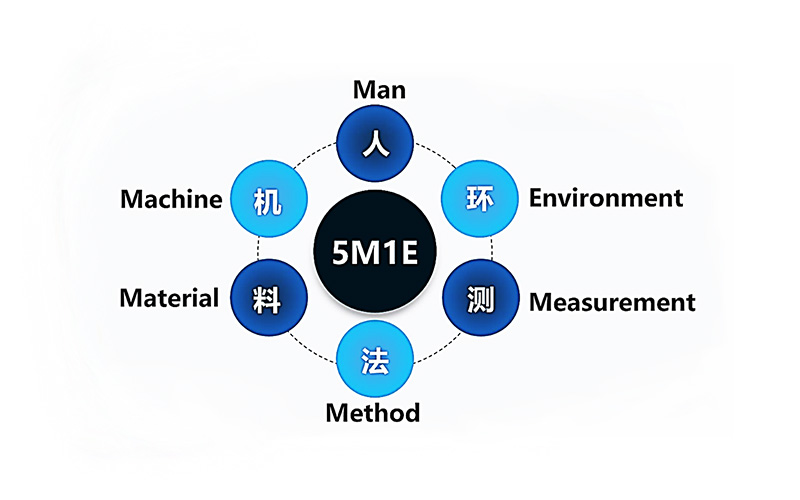

Quality is the conformance of the products or services we deliver to our customers with what we promise them. A consistent process determines consistent results. To ensure quality, it is necessary to monitor and manage the variations of elements including “man, machine, material, method and environment” in the product realization process with appropriate measurement methods.

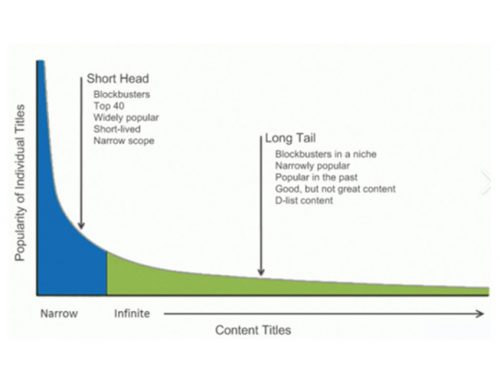

In terms of quality definition and method, the quality control of the high-mix low-volume wiring harness is consistent with that of the high-volume wiring harness. However, in a specific implementation, due to the differences between the realization process of the high-mix low-volume wiring harness and that of the high-volume wiring harness in new product introduction, material availability and production organization mode (for details, see: Difference between High-mix Low-volume Wiring Harness Business and High-volume Wiring Harness Business), the quality control of high-mix low-volume wiring harness is more challenging. The details are shown as follows:

Man

Implementing “management over post qualifications” is an effective means to manage the variation of personnel. In the past, we have utilized the “management over post qualifications” method in the field of mass manufacturing. This involves dividing posts by processes and implementing management over post qualifications. However, in management practice, we have found that we cannot solely focus on one type of wiring harness, unlike our counterparts who engage in high-volume wiring harness manufacturing. For instance, if the entire factory focuses on mobile phone USB cables, there are only a few types of processes, usually around 10 processes corresponding to 10 posts, with many people at each post. Therefore, it is feasible and economical to implement management over post qualifications according to process division. We have processed over 3,000 types of wiring harnesses, involving nearly 80 processes. If we follow the practice of dividing posts by process for high-volume wiring harnesses, and each post is divided into three levels: internship, qualified worker and coach to manage skills, we will be faced with management of about 80 positions and 240 skill levels. The management over post qualifications will be very complicated and cannot be implemented effectively.

After recognizing this issue, we made significant changes by combining the skill and quality requirements for different operator processes. Based on these criteria, operators are classified into three positions: general worker, multi-skilled worker and skilled worker. Each position is further divided into three levels of proficiency: internship, qualified worker, and coach. This simplifies the management over post qualifications and establishes a foundation for effective management.

Machine

In the management of machines, the general idea is the same for high-mix low-volume wiring harness manufacturing and high-volume wiring harness manufacturing. The acceptance, maintenance and repair of equipment are planned to ensure the stability of equipment performance. However, due to the low production quantity of high-mix low-volume wiring harnesses, the following two points need attention:

- For 80% of our wiring harnesses, the one-time processing task is less than 50PCS, and the production process is discontinuous. Therefore, it is not possible to assess the equipment’s process capability by calculating Cpk or Cmk through inspection data as in the case of high-volume wiring harnesses. Processing tasks with a number of over 30 PCS need to be specially scheduled regularly so that there are enough samples to calculate Cpk or Cmk to measure the stability of the equipment.

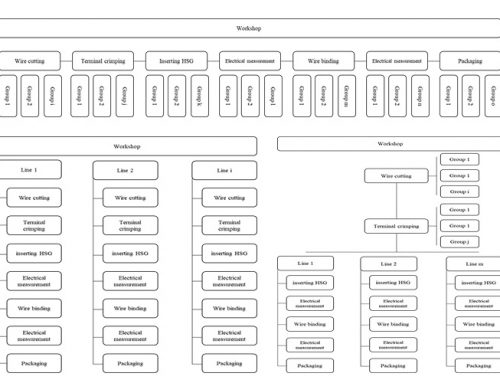

- Due to the low production quantity, numerous part numbers being produced in parallel, and frequent line changes, it is nearly impossible to produce high-mix low-volume wiring harnesses on automatic or assembly lines. The production can only be carried out by a combination of process automation, semi-automation, and manual methods. There are many human factors. Therefore, when considering the influence of equipment on quality, it is necessary to pay attention to the “fool-proof” function of equipment, so as to overcome human factors and achieve consistency in the manufacturing process.

Material

The terminal equipment of high-mix low-volume wiring harnesses is often adaptively designed or configured according to the requirements of end customers. Therefore, it is difficult to make sales forecasts, and the demand for materials fluctuates greatly. It is often forced to do material “risk procurement”, that is, purchasing materials from non-qualified suppliers or temporarily replacing materials. To control this variation, on the one hand, we should hold an “MRB” meeting in advance to identify possible risks and clarify corresponding control measures. On the other hand, we should pay attention to the investment and construction of IQC inspection ability in our daily management.

Environment

Except that some wiring harnesses in contact with or intervening in the human body have special requirements for the production environment, most industrial and medical wiring harnesses have no special requirements for the environment. Usually, 5S and anti-static measures are sufficient.

Method

Operation standardization is an important means of quality assurance. We realize the operation standardization in the production process of high-mix low-volume wiring harnesses through the following measures:

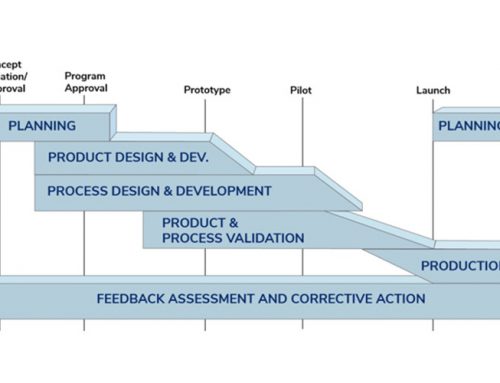

- As mentioned in the article “New Product Introduction of High-mix Low-volume Wiring Harness”, we rely on the idea of APQP tools to do things right at one time, realize the inheritance of experience through a structured process document system and process knowledge base, and quickly prepare clear and specific SOP for each wiring harness.

- Following the principle of lean production, we carry out research on operation units and optimize and solidify the operation environment for each process.

Through the above two measures, combined with the aforementioned personnel management over post qualifications, the problem of production operation standardization of high-mix low-volume wiring harness is solved, and the consistency of operation is ensured.

Measurement

The measurement process does not change the form of the product and is not a value-added behavior. The measurement link is important because there is inevitably the possibility of variation in “man, machine, material, method and environment” during product realization. It is necessary to monitor and manage possible variation through inspection. Therefore, the inspection must be planned and implemented based on product characteristics and our actual quality performance to avoid waste of redundant measurement or the risk of insufficient inspection. We realize the necessity and effectiveness of inspection items through the following measures:

- In addition to the structured process document system and process knowledge base, we have also built a structured PFMEA base and control point base. When new wiring harnesses are introduced, it supports us to quickly prepare special control plans for each wiring harness.

- We regularly summarize the exposed quality problems, and optimize and maintain the PFMEA base and control point base to ensure their effectiveness.

- As mentioned above, we realize that the production quantity of high-mix low-volume is low and it is impossible to monitor the process by calculating Cpk or Cmk through inspection data. Therefore, on the one hand, we pay attention to product inspection and carry out 100% full inspection on important characteristics of wiring harnesses; on the other hand, we regularly specially arrange processing tasks with a number exceeding 30PCS, and use full inspection data to calculate Cpk or Cmk to measure the consistency of the process.

Correct ideas determine correct actions, and we firmly believe that consistent processes determine consistent results. By carrying out effective “measurement” and monitoring and managing elements such as “man, machine, material, method and environment”, we have better solved the quality control challenge of high-mix low-volume wiring harnesses. At present, the DPPM is less than 50PPM, which is at the leading level in the industry, and we believe that we can do better.

All rights reserved: Shenzhen Hilink Technology Co., Ltd. Reprinting is welcome, but please be sure to indicate the source.