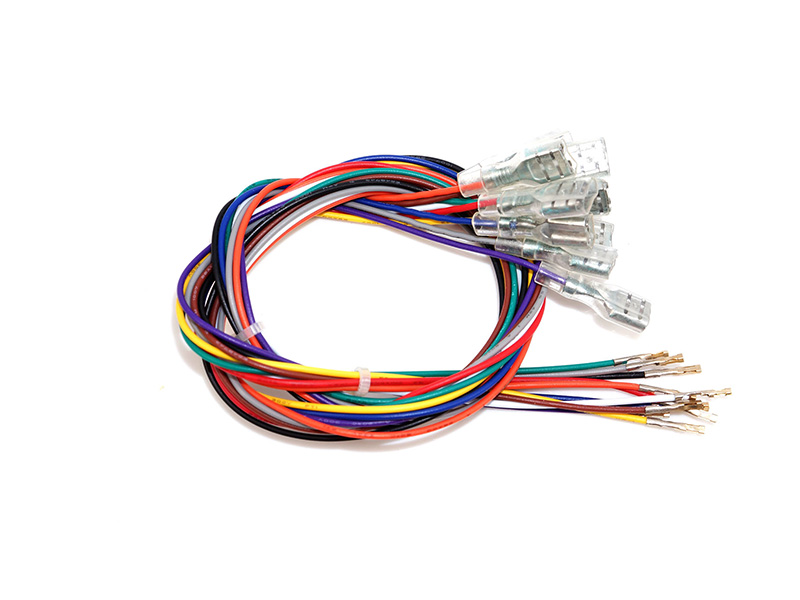

New Product Introduction of High-mix Low-volume Wiring Harness

Compared to the high-volume wiring harnesses, the new product introduction process of high-mix low-volume wiring harnesses has the following characteristics or challenges:

Compared to the high-volume wiring harnesses, the new product introduction process of high-mix low-volume wiring harnesses has the following characteristics or challenges:

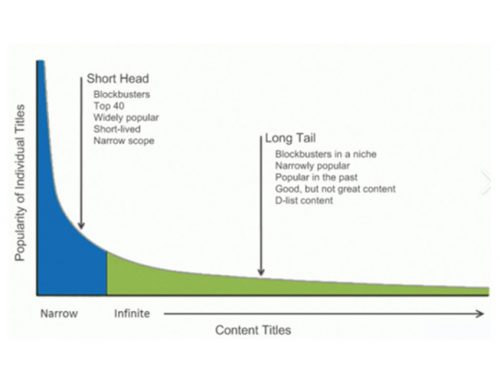

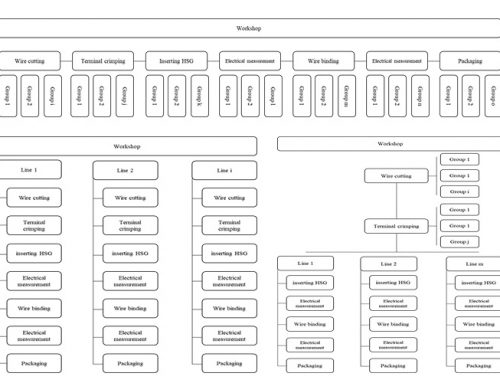

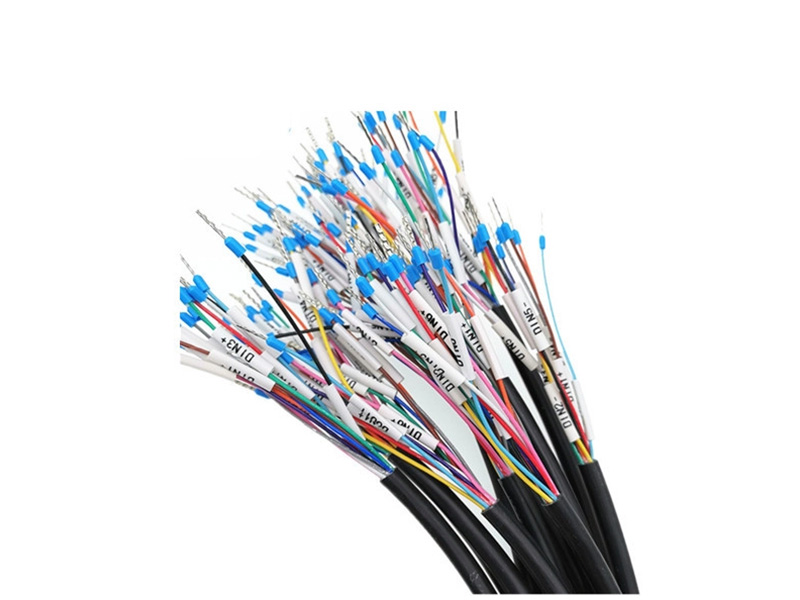

- As customers demand high-mix low-volume wiring harnesses, the demand for a single wiring harness part number is not significant. To obtain more bargaining power and concentrate on handling potential supply risks, the customers’ purchasing personnel often prefer to package all the wire harnesses for a certain model. They entrust it to a wiring harness supplier with an overall price advantage for the project, instead of comparing prices by individual part numbers as in high-volume wiring harness procurement and placing orders for a specific part number to a wiring harness supplier with price advantages under that part number. The practice of high-mix low-volume wiring harness customers placing orders according to projects results in that there are many wiring harness part numbers for each new product introduction. Based on our experience in the industrial and medical fields, there are usually 50 to 100 types of wiring harnesses for one model, and even over 300 types for a complex model.

- As the terminal equipment for high-mix low-volume wiring harness is often a customized solution for specific application scenarios of customers, it is typically sold on a project basis. This characteristic leads to the following challenges: On the one hand, equipment manufacturers have to make targeted designs or configurations for the application scenarios of end customers, and accordingly the equipment wiring harness needs to be adjusted adaptively. On the other hand, for terminal equipment, the wiring harness is a non-core component with low priority. In the whole project, there is a very short time left for wiring harness manufacturers to introduce wiring harnesses.

- The aforementioned two challenges bring another challenge: wiring harness manufacturers do not have time or enough volume to share the cost of wiring harness realization. For instance, improving the process design through multiple sample preparations and repeatedly accepting the process design through multiple trial productions. Therefore, it is necessary to find a way to do a good wiring harness introduction at one time.

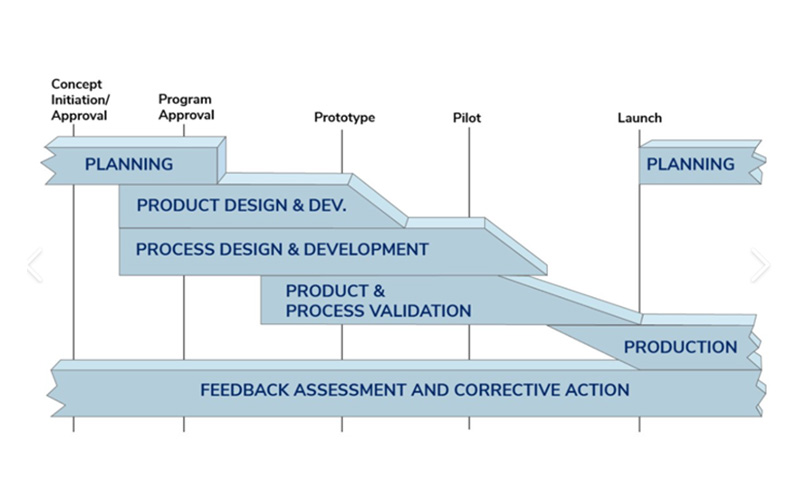

The above challenges constitute the “challenge triangle” of the wiring harness introduction process: time, quality and cost. We address this “challenge triangle” by organizing our new product introduction process using the APQP methodology. APQP is the abbreviation of advanced product quality planning, which is a structured method. It divides the product realization process into five stages: planning; product design & development; process design & development; product & process validation; and production, use & service. It emphasizes putting quality planning, control and improvement work in advance and pursuing to do things right at one time, as shown in the following figure.

Strictly speaking, the new product introduction of wiring harness only corresponds to two stages in the above figure: process design & development, and product & process validation. However, as we pointed out in “Difference between High-mix Low-volume Wiring Harness Business and High-volume Wiring Harness Business”, “(Customers) are unable to allocate dedicated professionals for the development of wiring harness, ….., the wiring harness is completed part-time in many cases by electronic engineers or structural engineers, who are experts in their own fields but often lack sufficient expertise and experience in wiring harnesses. In view of this, it is necessary for the harness supplier to understand the customer’s application, follow the principles of value engineering, and combine harness expertise to provide professional harness design or optimized design support for the customers.” Therefore, in the process of high-mix low-volume wiring harness introduction, we cannot limit ourselves to the aforesaid two stages, i.e. process design & development, and product & process validation. Instead, we should further expand to cover all five stages of the APQP process. The practice is as follows:

Planning stage

To ensure effective support for customers, it is necessary to confirm that our actual situation can effectively support the customer’s project to be transferred at this stage.

Product design & development stage

- Based on the “Manufacturing Feasibility Report” template, conduct a wiring harness design review of the customer’s transfer project in terms of compliance, importance, reliability, assemblability, detectability, availability and cost efficiency, and provide professional advice to the customer.

- Based on the customer’s application scenario, use our expertise to assist the customer in implementing VAVE.

- Make wiring harness samples and cooperate with customers in the design and development of terminal products.

- If necessary, cooperate with customers to carry out a “type test” of the wiring harness and finalize the design of the wiring harness.

Process design & development stage

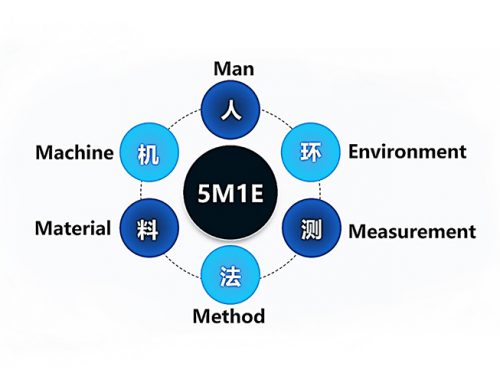

- Utilize the structured process documentation system and process knowledge base to output specialized PFMEA, SOP, and quality control plans for each type of wiring harness.

- Quickly improve the process design through an agile and efficient sample process.

Product & process validation stage

Organize trial production and acceptance process design.

Production, use & service stage

Continuously improve the quality, delivery and cost performance.

Just as Musk was not the inventor of the First Principle Thinking, we are not the inventor of the APQP tool. However, we can learn from Musk, respect the wisdom of our predecessors, and thoroughly implement these historically proven methods to their fullest extent to deliver competitive products or services to customers.

All rights reserved: Shenzhen Hilink Technology Co., Ltd. Reprinting is welcome, but please be sure to indicate the source.