Introduction to Value Engineering and Its Application in the Wiring Harness Industry

Value Engineering (VE) is a systematic management technology and innovation methodology. Its core objective is to provide the best scheme that

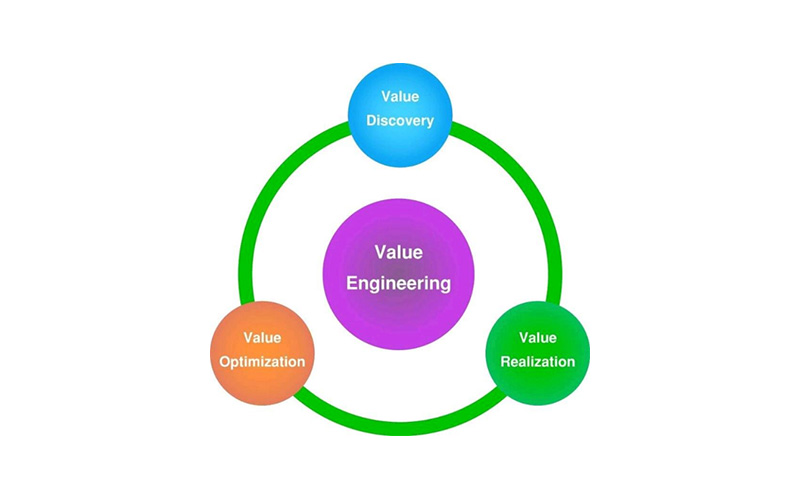

Overview of Value Engineering

Value Engineering (VE) is a systematic management technology and innovation methodology. Its core objective is to provide the best scheme that meets the functions required by users at the lowest life cycle cost through functional analysis of products or services, thus improving the value of products. Value engineering emphasizes reducing costs without affecting or even improving the quality of products or services on the premise of ensuring product performance and service level.

The formula for calculating value in value engineering is as follows:

V=F/C, where V is value, F is function and C is cost。

The formula outlines five methods to enhance product value:

- Improve functions and reduce costs, F↑/C↓=V↑.

- Improve the function, and keep the cost unchanged, F↑/C→=V↑.

- Greatly improve the function and slightly increase the cost, F↑↑/C↑=V↑.

- Keep the function unchanged, and reduce the cost, F→/C↓=V↑.

- Slightly reduce the function, and reduce the cost greatly, F↓↓/C↓=V↑.

Why should we implement value engineering?

- VE is a globally recognized management technique for reducing costs and improving economic efficiency.

- The concept of VE is applied in a very wide range and can be widely used in many different industries.

- The benefits of VE are quite obvious. Most projects can obtain a 10%-30% cost reduction while meeting the performance requirements and increasing enterprise profits.

- The application of VE can stimulate team innovation and improve the market competitiveness of products.

Implementation steps of value engineering:

- Object selection: identify products, services or processes that need improvement.

- Functional analysis: define the core functions of products or services and their importance levels.

- Functional evaluation: conduct a quantitative evaluation of the cost of an existing solution and the functionality it provides.

- Innovative thinking: look for alternative design schemes, optimize function realization methods and reduce unnecessary costs.

- Scheme generation and screening: create and compare multiple possible improvement schemes.

- Scheme implementation: select the optimal scheme and develop an implementation plan.

- Effect verification: Evaluate the improvement results after implementation to ensure value enhancement.

Application of Value Engineering in the Wiring Harness Industry

In the wiring harness industry, we can achieve the following with VE:

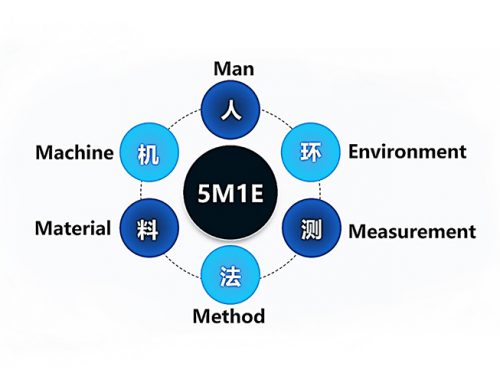

- Design optimization: The VE method is used to determine the reasonable characteristic requirements of equipment for the wiring harness, and unnecessary circuits are eliminated to avoid specification redundancy. DFX design is carried out to ensure the realization of reliability, maintainability, manufacturability and assembly objectives, so as to realize the optimal design of wiring harness.

- Material optimization: As the wiring harness is a module connecting the electrical system, its material selection directly affects the cost and performance. Through value engineering, we can effectively carry out material selection and substitution according to the application scenarios of equipment, so as to achieve lower material costs and better material availability on the premise of ensuring the functional performance of equipment.

- Process improvement: By analyzing the whole process of wiring harness production, we can identify unnecessary waste and optimize the process, such as reducing time waste and avoiding excessive production. We can improve the process by pursuing balance, implementing process automation, combining processes and other measures to improve efficiency and quality, so as to reduce harness processing costs and save quality costs.

- Life cycle cost reduction: We can analyze all links in the whole life cycle of the wiring harness from design, production, installation and use to scrapping and recycling, select appropriate methods to enhance the value of each link and realize the optimal life cycle cost of the wiring harness.

In a word, by conducting value engineering, we can continuously find innovative opportunities in such a traditional field as wiring harness, constantly create value for customers and assist customers to build competitiveness, thus making ourselves competitive. In addition, value engineering can save costs without harming the interests of any party involved compared to other means of cost saving, so it is sustainable.

All rights reserved: Shenzhen Hilink Technology Co., Ltd. Reprinting is welcome, but please be sure to indicate the source.