How can High-mix Low-volume Wiring Harness Manufacturers Help Customers Save Costs?

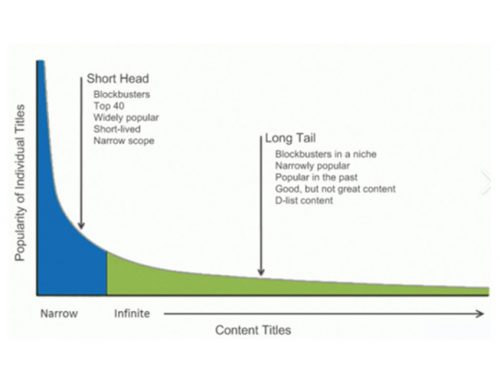

The terminal products corresponding to the demand for high-mix low-volume wiring harnesses are usually the equipment in the industrial medical industry

The terminal products corresponding to the demand for high-mix low-volume wiring harnesses are usually the equipment in the industrial medical industry. Although these equipment have complex structures, advanced technology and correspondingly high prices, it does not mean that there is no competition between them. On the contrary, compared with consumer products, the end customers of these equipment are more concentrated, the market is smaller and the competition is fiercer, so they need the support of suppliers more.

The high price of industrial and medical equipment also poses a challenge to wiring harness manufacturers: the proportion of wiring harnesses in their total cost is relatively low. According to our experience, the cost of wiring harness usually accounts for less than 5%, and even as low as 2‰. As a wiring harness manufacturer, focusing solely on the price of the wiring harness itself limits the cost savings we can offer to customers. We must think about how to help customers save costs and cope with the fierce market competition in a wider scope.

How to do it?

- Reduce the price of wiring harness and help customers save on the procurement cost of wiring harness

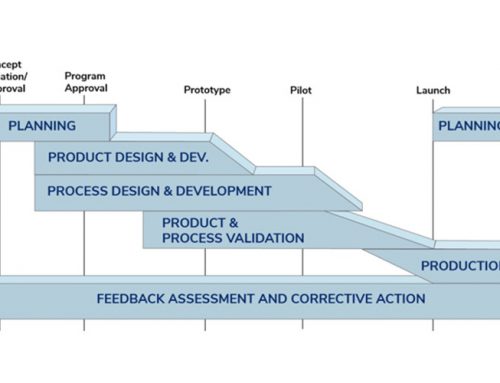

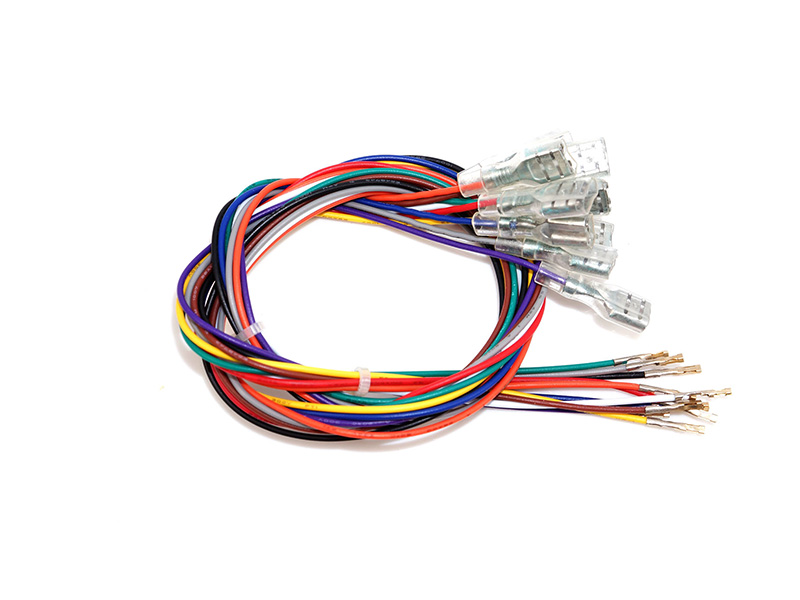

High-mix low-volume wiring harnesses in the industrial and medical fields are usually customized non-standard wiring harnesses, and the wiring harness manufacturer is essentially a contract manufacturer that carries out wiring harness manufacturing services according to the customer’s wiring harness design and BOM. If we keep this traditional cooperation model with our customers, and only negotiate the price of wiring harness materials or carry out process improvement, the cost savings we can achieve are very limited.

It is more effective to interact closely with customers and assist them in normalizing wiring harness materials so as to reduce the types of wiring harness materials. We need to fully understand the functional performance requirements of customer’s equipment for wiring harnesses, assist customers in reducing redundant design, determine reasonable material specifications, and avoid waste caused by redundant design and material specification redundancy. We need to combine the quality, delivery and price performance of material suppliers, assist customers in establishing a material preference list, support customer’s material selection in the process of new product development and material substitution in the process of cost optimization of existing products, and maximize the concentration of customer’s discrete material requirements on advantageous models of dominant suppliers, so as to obtain better quality assurance, delivery coordination and cost saving. In the process of serving customers, we have helped customers achieve more than 50% price reduction through such efforts many times.

- Assist customers in improving the assemblability of wiring harnesses and help them reduce equipment assembly costs

Industrial and medical equipment has advanced technology and high requirements for practitioners. To obtain high-quality talent, R&D departments are usually set up in first-tier cities with high costs, such as Beijing, Shanghai, Suzhou and Shenzhen. At the same time, due to the relatively high number of customized designs or configurations for industrial and medical equipment, close interaction between research and development and factories is required. The factories that determine industrial medical equipment are usually located in first-tier cities, resulting in high equipment assembly costs.

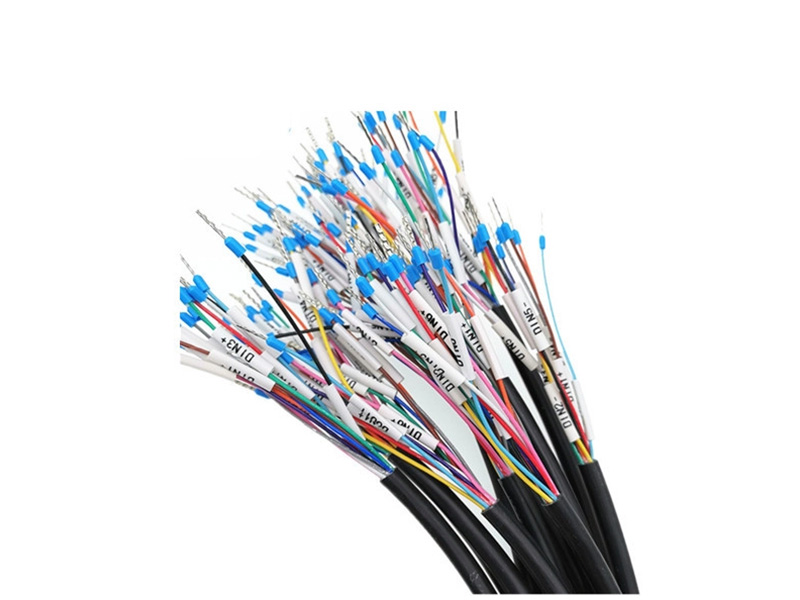

In this case, wiring harness manufacturers must understand the assembly process of customers’ products and assist them in improving the assemblability of wiring harnesses, enhancing assembly efficiency and saving labor and site costs. We once helped customers integrate 106 cables of a model into 3 sets of wiring harnesses, reducing the assembly time of equipment wiring harnesses from 120 minutes to 21 minutes, and reducing the area of the assembly workshop from 600m2 to 150m2, thus saving considerable labor costs and site costs.

- Ensure the quality of the wiring harness and help customers save quality costs

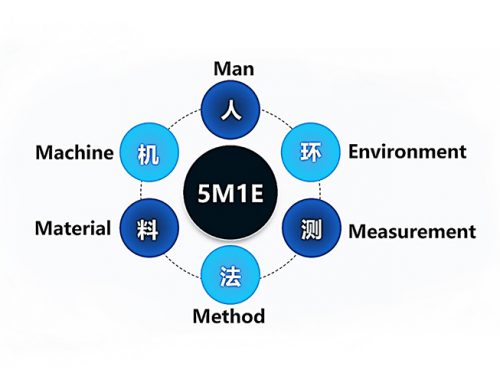

By setting up reasonable inspection nodes, configuring effective measurement means, monitoring and managing the “man, machine, material, method and environment” and other elements of the wiring harness production process, a consistent process is established to ensure the consistency of wiring harness quality and help customers reduce the quality cost of production process and after-sales service. (For details, please refer to “Quality Control of High-mix Low-volume Wiring Harnesses”.)

- Provide JIT delivery to help customers save stock costs

By developing a special ERP system to maintain flexible material supply, we establish an agile and high-quality production system, keep close interaction with customers, provide JIT delivery of high-mix low-volume wiring harnesses for customers, help customers improve stock turnover rate, reduce stock space and reduce capital occupation in stock. (For details, please refer to “How to Establish a Reliable Supply Guarantee for High-mix Low-volume Wiring Harnesses”.)

It is through such sustained efforts in various aspects that we are fully committed to continuously contributing value in the field of high-mix wiring harness manufacturing, standing firmly with our customers, serving as a strong backing for them, and facing up to the fierce competition together.

All rights reserved: Shenzhen Hilink Technology Co., Ltd. Reprinting is welcome, but please be sure to indicate the source.